Product Description

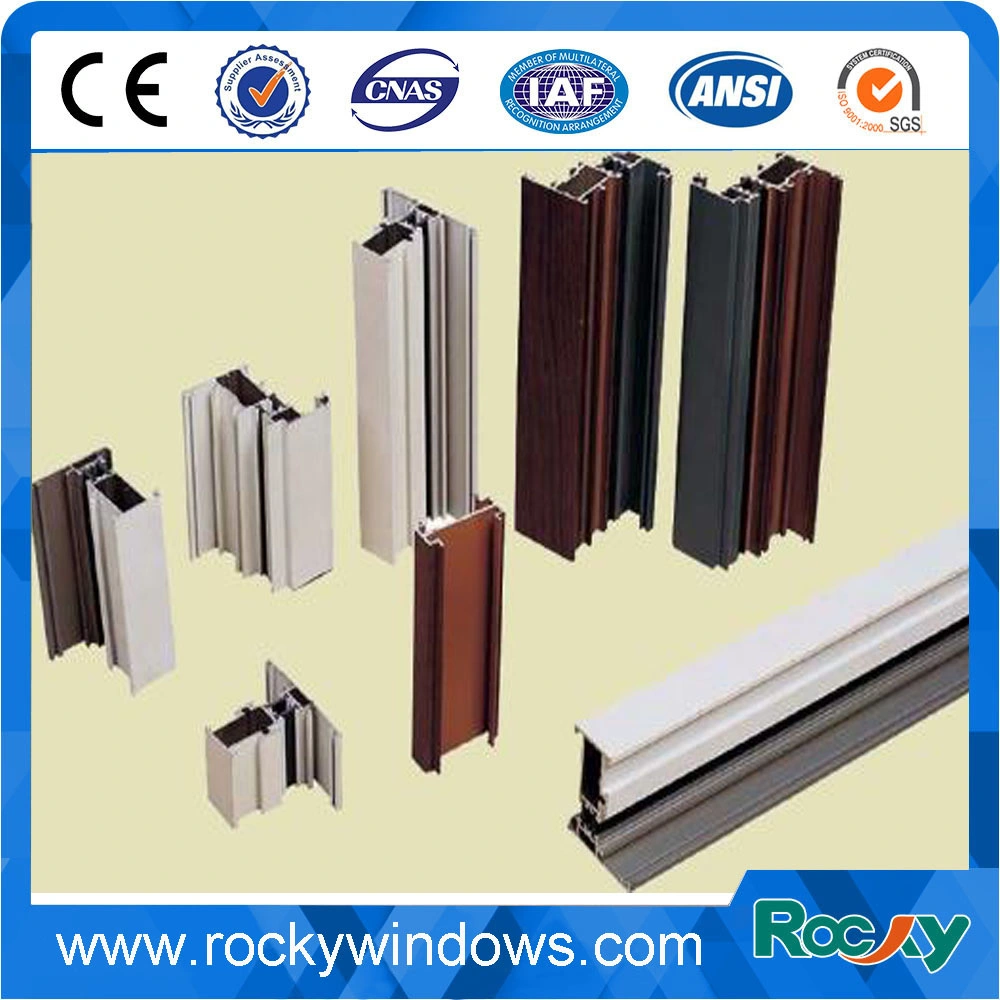

1. Material: Aluminium alloy 6063,,6061,6463,6061,6082,6060,6005 or according to customer's request2. Temper: T5, T6

3. Surface treatment: Mill finish, anodized, powder coated, electrophoresis, sand balsting etc. PVDF coating, wood grain painting, matted, polishing bright

4. Color avalilable: Silver, Bronze, champagne ,Matte,Natural for andodizing, Ral for powder coating

5. Packing details: Protected film inside and shrinking film outside

6. Samples time: two weeks after receive the mold fee

7. Delivery: 20 days after deposit

8. Production Capacity: 5000MT/Month

9. MOQ: 10 TONS

10. Port: QINGDAO PORT

11. OEM & ODM service.

The Advantage of ROCKY Extruded Aluminum Profiles Are Built In.

For manufacturers and fabricators offering high-quality, reliable and high performance building products, the ROCKY advantages come standard.

- New Construction, Replacements or both.

- Residential,Commercial Housing.

- Thermal performance requirements.

- Structural performance requirements.

- Impact requirements.

- Maximum insulated glass thickness requirements.

- Compatibility with existing products.

- Fabrication requirements.

- Cost criteria.

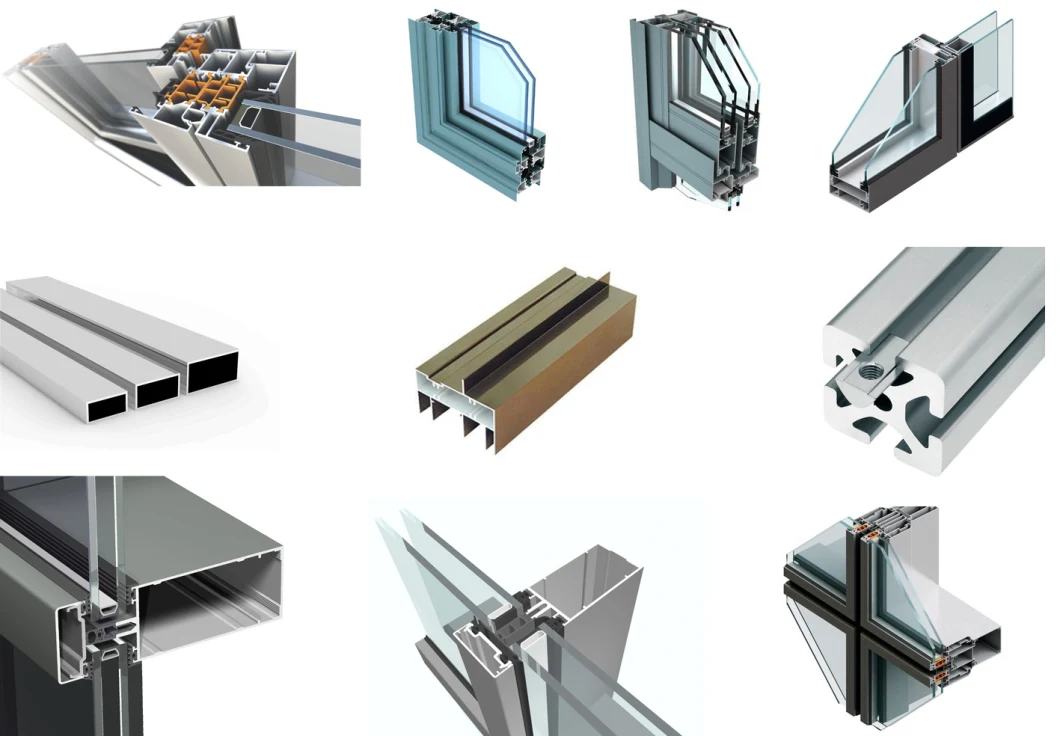

- Varied width frame depth to accommodate varying types of applications.

- Thickness:0.6-3mm.

| Brand: | Rocky |

| Material: | Alloy-6063-T5, 6061-T6 |

| Surface Treatment: | Anodize, Powder coating, Mill-finished,Wood-finished |

| Color Option: | Silver,Champage,Bronze,Golden,Black,Sand coating, Matt silver or Customized |

| Film standard: | Anodized: 7-23micron |

| Powder coating:40-120micron | |

| Electrophoresis film :12-25micron | |

| MOQ: | 10-12Tons/1*20', 20-23Tons/1*40' |

| Length: | 5.8M/6M/6.4M |

| Contact | Colin +8618763902831 |

| Configurations: | Sliding Windows/Sliding Doors |

| Casement Windows/Swing Doors | |

| Awning Windows. | |

| Fixing Windows. | |

| Folding Doors |

About Rocky Development

Rocky Development Co.,Ltd (Qingdao Rocky Window Co.,Ltd) is fast growing manufacturer& supplier of window, doors as well as aluminium extrusion profiles. We offer a wide range of products to residential, commercial, industrial applications. Operating from a state of art fabrication facility base in Qingdao, China. Our technologically advanced products are readily available to demanding clients for new construction, replacement, remodeling and upgrading.

At Rocky,our primary goal is to ensure a pleasant experience for our valued customers. Rocky customers not only benefit from our quality products and competitive prices, but also personalized service,flexibility,short lead time and reliability as well. Rocky aluminum profile is committed to the highest standards, assembling your contemporary demands for living quality, environmental harmony, and energy efficiency.

Package & shipping:

Shrink film or paper

FAQ

What is your delivery time

Rocky: it is within 20 days for one 20' container.

What is your sample policy

Rocky: The sample is free, you have to pay the freight charge. The sample will be finished one week.

What is Quality Control system?

Rocky:

5 steps:

A, After order confirmed, we have a meeting with the main peoples who work for workshop before production,investigate all the workmanship and some technical problems, ensure all of them have related ways to settle and control.

B, Inspect all the materials when arrived, ensure they will be catched up customers's requirements.

C, Inspect the semi-finished goods.

D, Inspect the finished products.

E, Final inspection when pack up all the goods.if there is not any problems for this step,our QC will issue the inspection report and release this products.